History

Molas Brusque, founded in 1984 by Mr. Carlos Roberto Fischer, our current

president. Willing to make a difference in the segment that he knew and

Always was passionate.

Always visionary and living in a region dominated by textile sector, found

na opportunity to produce spare parts and offer maintenance for these

machines.

With our commitmentr emerging market and the rising of several demands in

others segments, Molas Brusque evolved to What it is today.

We offer quality, assurance and compliance, as well as solutions in the

development of our customer's products, which provide the necessary

satisfaction in such a competitive industry.

We are located in the southern region of Brazil, in the City of Brusque, in an industrial park of more than 52.000m2 apart from 9,200m2 on built area. We are proud to be present throughout Brazil and other countries.

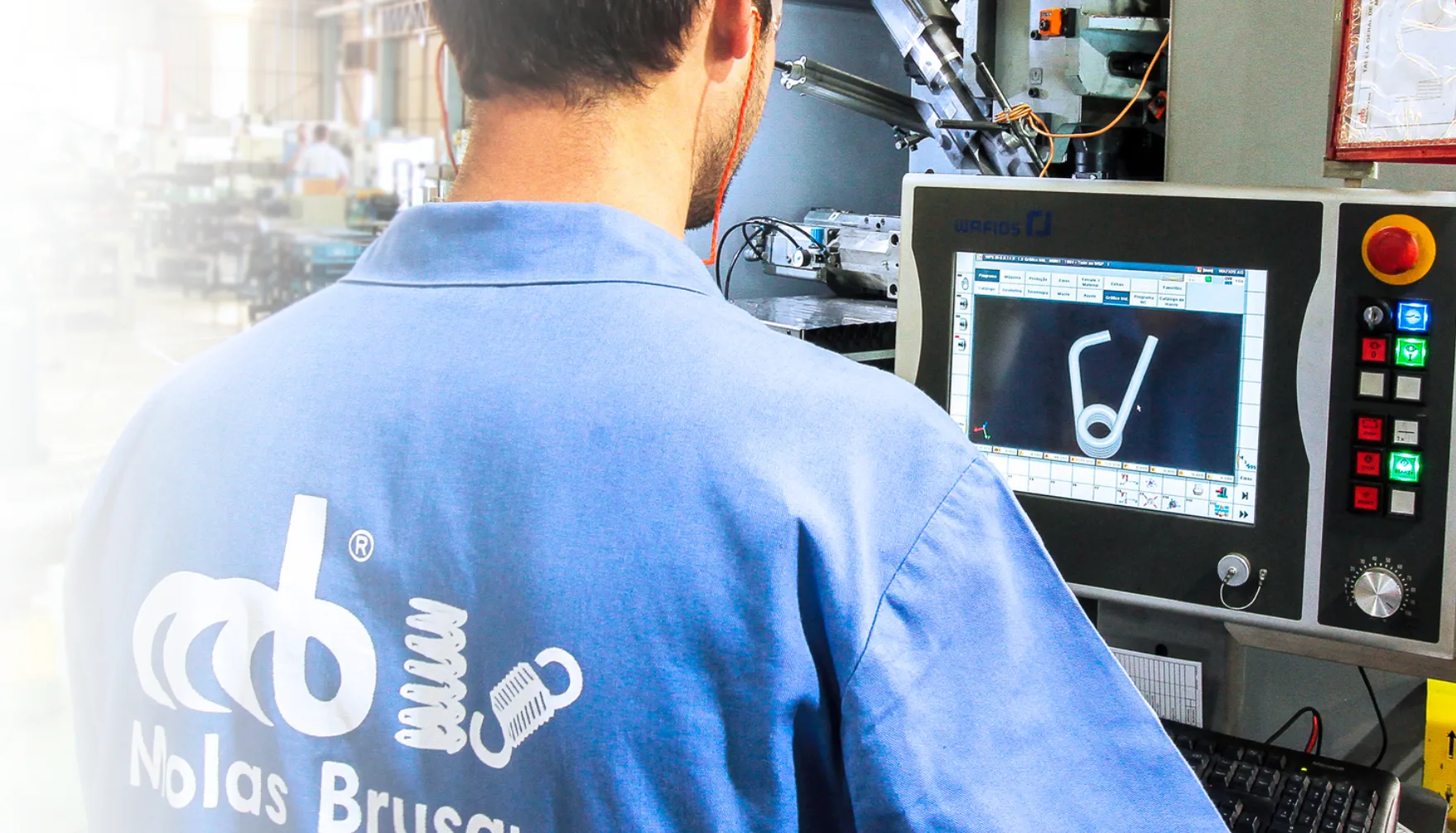

Technology

Technology is one Of the Pillars Of our Company. Since the beginning,

looking for the best and most modern equipment for the manufacture of

springs and wire artifacts on the market.

Our production area has CNC technology in its entiretyr consequently

becoming the most advanced company Of this segment in the South of the

country, and one of the main ones throughout the national territory.

Quality and Certification

In addition to the 39-year know-how, continuous investments and well-defined

processes, Molas Brusque guarantees quality, skill, knowledge and experience

by having ISO 9001 and IATF16949 certification.

According to premises established in our Quality Policy, we contínually seek

to improve the production and management processes, where technology and

employees are our main foundations.

The requirements deployed in the process with the customer is guaranteed by

means on traction, compression, fatigue, torsion, and salt-spray tests,

which are carried out in the fatigue, metrology and chemical laboratories,

duly equipped to withstand the demands of each product or process performed.

This set is What makes Molas Brusque meaning of quality trust, perceived in

the final product.

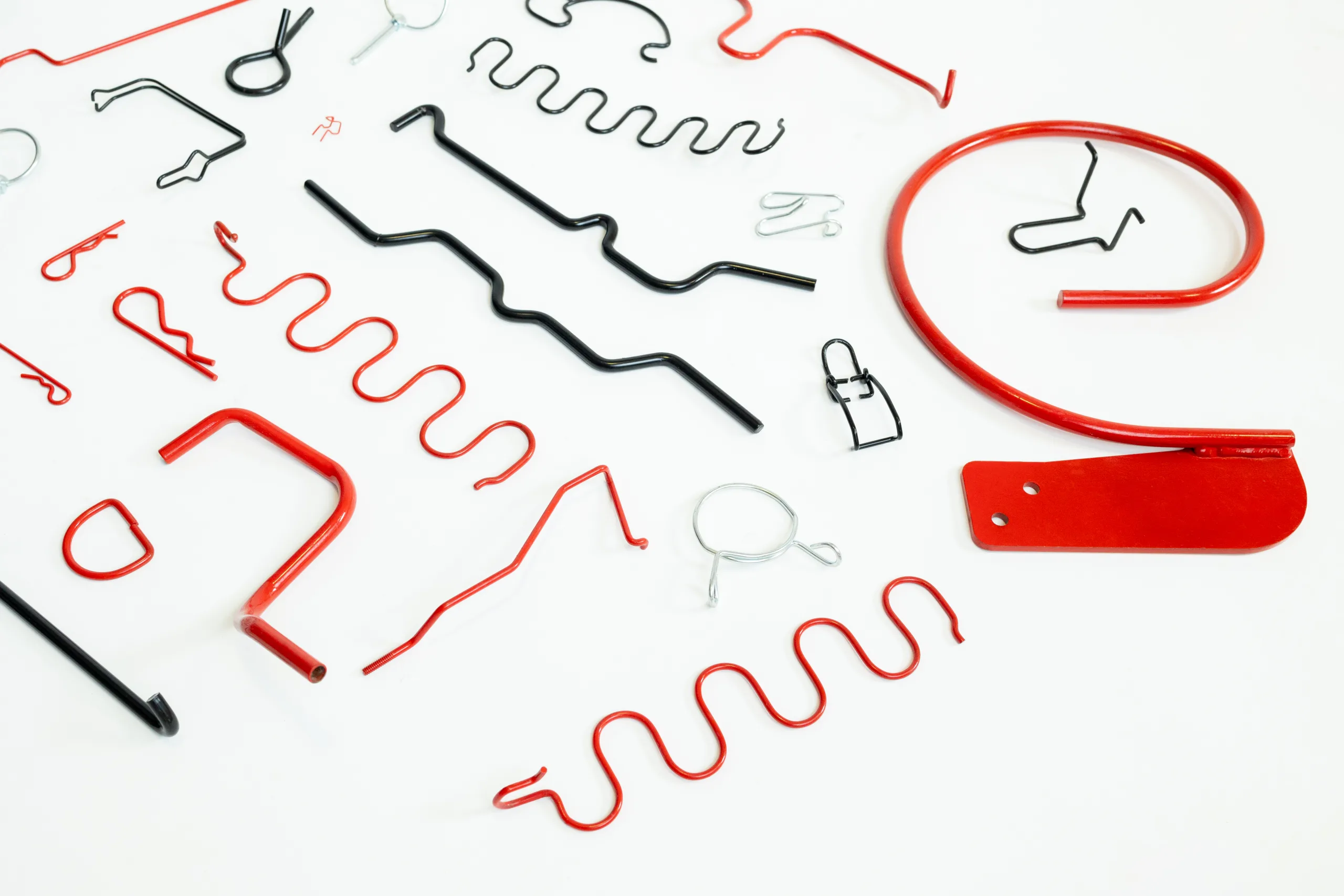

NOSSOS PRODUTOS

Molas Brusque possui equipamentos de alta tecnologia e trabalha em parceria com seus clientes oferecendo soluções no desenvolvimento que proporcionam produtos com qualidade a preços competitivos.

The constant updating in our technology park enables a diversity Of options and flexibility of manufacturing lots of springs and Wire parts. Our knowledge stands out in extension springs, compression springs, helical springs, conical springs, magazine springs, spiral springst torsion bar and wire parts.

With CNC Equipment producing our products, we Offer high quality and performance associated excellent accuracy in gauges ranging from 00,10 to 027,OOmm.

We use Iow, medium and high carbon wire, oil tempered, stainless, copper and other alloys. Our processes include stamping, lamination, grinding, shot-peening, assembly, welding, among others. In addition, the final process in surface treatments of chromate coating, e-coat, painting, etc.

We are present in all major markets such as agricultural, automotive, appliances, machinery and equipment, furniture, plastic and similar.

Extension Spring

Ø0,10 à Ø16,OOmm

Torsion Spring

Ø0,10 à Ø16,OOmm

Compression Spring

Ø0,10 à Ø27,OOmm

Wire Parts

Ø0,10 à Ø13,OOmm

Major Markets

ESG

Molas Brusque is continuously aware to our most valuables commitments:

health, safety, sustainability and the environment, even going beyond our

legal and economic obligations.

We are committed to compliance policies and sustainable results by

providing a safe and healthy work environment for our employees,

maintaining corporate integrity at all levels and investing in solutions

so that our company can grow in harmony with What we believe.

We are constantly involved with environmental management centers,

developing our products in a way that minimizes the negative impact of

EHS, and continue to move in favor of the environment, sustainability and

society